-

Accumulation / Conveying

accumulation-conveying

-

6000 Series Conveyors

A proven solution to maximize production.

Increase Throughput by 30%

Raised Werastrip Converyors

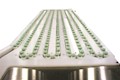

Garvey® Corporation's 6000 series "Raised Wearstrip" conveyors are designed to carry nearly any product and work well in nearly any application in the pharmaceutical, food, or cosmetic industry. For easy maintenance and product protection, this conveyor incorporates a unique raised wearstrip design that permits debris to fall free. The conveyor's top is raised, and this allows easy detection of particulates under the conveying surface. The Series 6000 conveyor is available in modular sections to permit more efficient use of floor space and to enable line changes to be made more economically. -

9000 Series Conveyors

A proven solution to maximize production.

Increase Throughput by 30%

The 9600 series conveyor is Garvey®'s standard solution to your conveying needs. They are designed to carry a wide variety of product at the widest variance of speeds. Its modular design allows for easy and quick design and re-design of your line. By choosing the pieces that fit your current conveying needs, Garvey® engineers can provide you with an exact solution quickly. -

GT Series Conveyors

A proven solution to maximize production.

The GT series conveyor is Garvey®'s latest innovative solution to your Table Top Conveyor System needs. The GT Series is designed to carry a wide variety of product at the widest variance of speeds. Its modular design allows for easy and quick design and re-design of your line. By choosing the pieces that fit your current conveying needs, Garvey® engineers use the latest 3D modeling software to provide you with an exact solution quickly. - Infinity™/RX Series Conveyors

-

Mat Top Conveyors

A proven solution to maximize production.

Mat Top Conveyor belts provide long life and high impact resistance. The Mat Top-style conveyors are perfect for almost all handling applications because the belt construction is ideal for easy cleaning and low maintenance.

The design flexibility is another benefit of the Mat Top Conveyors since they allow for ease of layout. The variety of interchangeable belts also allow products to be transported in minimum floor space.

The belts we use provide a quiet, smooth, trouble-free performance. -

BI-FLO® Accumulation Tables

Increase throughput by 30%

- Avoid damaging back pressure & line shut down.

- Product free-flows onto the table, constantly moving in two directions.

- Accumulate and store square, oval, round and rectangular containers, as well as product in a puck or fixture.

- Gain up to 30% additional output from your existing line.

-

Infinity™ Accumulation Tables

A proven solution to maximize production.

The Infinity™ Accumulation Table uses our patented technology to accumulate and single file even the most unstable of products at speeds that are unmatched in the industry. Using their patented loop technology, Garvey® handles products with no backpressure, no breakage, no label damage and minimal noise.

The Infinity™ Accumulator is a zero pressure accumulation system that is surprisingly simple, efficient and easy to maintain. This patented system can be installed as a multi-laning device, a buffer system or an unscrambler. It can also orient and flip products. -

Infinity™ RX Accumulation Tables

A proven solution to maximize production.

Garvey®'s Infinity™ RX is the best solution for handling vials and other small, unstable products. Never before has it been so easy to protect the throughput of your production lines. Garvey®'s Infinity™ RX Series provides high-speed, low backpressure accumulation at previously impossible rates. This machine flawlessly handles products prone to instability and damage.

The Infinity™ was designed to meet the needs of industries with the strictest regulations. All interior surfaces can be angled in order to prevent foreign materials from collecting, and metal-to-metal surfaces have been minimized to eliminate entrapment. -

Infinity™ Series Accumulation Tables

Increase Throughput by 30%

U.S. Patent # 6,575,287; 6,612,425; 6,612,417 & 6,648,124; 6,959,802 & 6,964,329 International Patents Pending

It's one thing to design and build good accumulators. It's another thing to know where to put them. Garvey® Corporation knows. By using our proprietary Line Analysis system, we can study your line, identify strategic locations, determine optimal size, and test machine rates for maximum line performance. This process has been used on hundreds of lines and has consistently yielded increases in throughput of 10 % to 40 %. -

Multi-Lane Bi Flo Accumulation Tables

Maximize Your Production

Garvey® Corporation designed this system to provide a way to feed a case packer with multiple flavors of milk. It was important to maintain segregation between flavors, while still providing a buffering system between the mentioned case packer and a labeler. Garvey® Corporation was able to achieve this by using only one accumulator, enabling valuable floor space to be efficiently utilized. -

Serpen Flo Accumulation Tables

- Low back pressure

- Multiple product handling capability

- 5 minute product change over

- Loose First-in-first-out Pattern

-

Serpentine Accumulation Tables

- Available in a wide variety of speeds and sizes.

- Accumulate unstable or difficult to handle products.

- Handle square, round, and rectangular products

- For accumulating with first-in first-out patterns, while at the same time maintaining orientation

-

Clean Room Transfer Systems

A proven solution to maximize production.

The Garvey® Clean Room Transfer is designed to minimize the size of the exit portal of a clean room while providing a flush chain to chain transfer, eliminating the need for dead plates. They are an effective solution as they allow products to be transferred into controlled environments without being handled. The unit can be located either outside or within the clean room. -

Gap Transporters

A proven solution to maximize production.

Increase Throughput by 30%

Garvey®'s completely portable transporter is a versatile workhorse. With the slightest of adjustments, it can be used for gap transporting and conveying, depucking, elevating, spacing, label inspecting, and bottom coding and inspecting. -

Garvey® Automatic Vial Dryers

The Automatic Vial Dryer speeds up the drying process from 24-48 hours down to as little as 5 minutes.

This process allows vials to go directly to labeling or inspection, reducing time out of refrigeration and labor.

The Automatic Vial Dryer utilizes a modular design and can be configured to fit in even the tightest production line layouts. Various in-feed and out-feed options are offered and the machine will handle products ranging from 2 ml to 50 ml lyophilized and liquid filled vials.

After drying, our high speed Infinity Rx accumulation table gently single files vials at rates up to 800 vials per minute using our patented pressureless loop Infinity technology. -

Gripper Elevators

A proven solution to maximize production.

Garvey®'s Gripper Elevator fits within existing conveyor lines with ease due to its minimal footprint design. The vulcanized gripper surface opens or closes with a built in handwheel, from less than 1" to a maximum of 12" separation (wider units are available upon request.) Infeed and outfeed elevations are designed to customer specifications and product can be lowered or raised depending on requirements.