| Items |

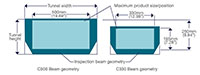

C330 Pro

Thermo Scientific™ NextGuard™ 1.5 Meter (m) Standard Conveyor Length Pro X-Ray Inspection System

|

C500 Pro

Thermo Scientific™ NextGuard™ 1.5 Meter (m) Standard Conveyor Length Pro X-Ray Inspection System

|

|

Description

|

N/A

X-ray inspection with rugged, flexible material handling

The Thermo Scientific™ NextGuard™ Pro X-ray Inspection System builds on the proven success of the standard Thermo Scientific™ NextGuard™ C330 models by adding more configurations and capabilities, expanding the range of addressable applications.

The Pro models offer a wide range of single-belt configurations with built-in rejection systems, shielding, heavy duty motors/rollers and stainless steel flange bearings for more demanding large package and wet applications. The conveyor can handle up to 5x more weight and can be extended in length up to 3.5 m with flexible, integrated, built-in rejection systems. The Pro can also utilize up to three AC variable frequency drives, making complex, multi-conveyor custom configurations possible.

|

N/A

X-ray inspection with rugged, flexible material handling

The Thermo Scientific™ NextGuard™ Pro X-ray Inspection System builds on the proven success of the standard Thermo Scientific™ NextGuard™ C500 models by adding more configurations and capabilities, expanding the range of addressable applications.

The Pro models offer a wide range of single-belt configurations with built-in rejection systems, shielding, heavy duty motors/rollers and stainless steel flange bearings for more demanding large package and wet applications. The conveyor can handle up to 5x more weight and can be extended in length up to 3.5 m with flexible, integrated, built-in rejection systems. The Pro can also utilize up to three AC variable frequency drives, making complex, multi-conveyor custom configurations possible.

|

|

Brand

|

N/A

NextGuard™ Thermo Scientific™

|

|

Maximum Product Weight on Conveyor

|

N/A

50 kg110 lb

|

|

Conveyor Heights

|

N/A

1100 mm800 mm950 mm31.5 in37.4 in43.3 in

|

|

Conveyor Heights Tolerance (±)

|

N/A

75 mm3 in

|

|

Standard Conveyor Length1

|

N/A

1.5 m59 in

|

|

Roller Diameter

|

N/A

70 mm2.8 in

|

|

Motion System

|

N/A

AC gear motor driven by variable frequency drive (VFD). Up to three VFDs to drive the system and two external conveyors.

|

|

Bearing Type

|

N/A

Stainless Steel Flange

|

|

Frame

|

N/A

System always utilizes a single stainless steel frame. Locking wheels optional.

|

|

Alternating Current (AC) Voltage

|

N/A

195 to 250 V

|

|

Frequency

|

N/A

50 Hz60 Hz

|

|

Number of Phase

|

N/A

1

|

|

Electrical Supply

|

N/A

Autosensing X Amps

|

|

Machine Weight

|

N/A

Contact Factory

|

|

Radiation Conformance Tests and Certifications2

|

N/A

Food and Drug Administration Code of Federal Regulations (FDA CFR) 21 Part 1020.40 Others RED Act (Canada)

|

|

Features

|

N/A

- Same base features, capabilities and ease of use as the standard NextGuard™ models

- Heavy-duty stainless frame, optional wheels

- Extendable in-feed and outfeed conveyors

- Easy disassembly for belt replacement

- Heavy-duty rollers, flange bearings and AC gear motor drive

- Available built-in reject bins with locking doors and reject verify/bin full

- Shielding to meet radiation requirements anywhere in the world

- Design flexibility for customized configurations

|

|

Additional Information

|

N/A

Built-in air blast or pusher rejection, stainless steel or lexan covers and lockable reject bins with reject confirmation/bin full sensors

Heavy duty rollers and stainless steel flange bearings

3/4 HP gear motor with variable frequency drive

|

|

Note

|

N/A

All NextGuard™ standard features and options are available on the Pro models.

|